At a Glance

- Client: Tony Bianco

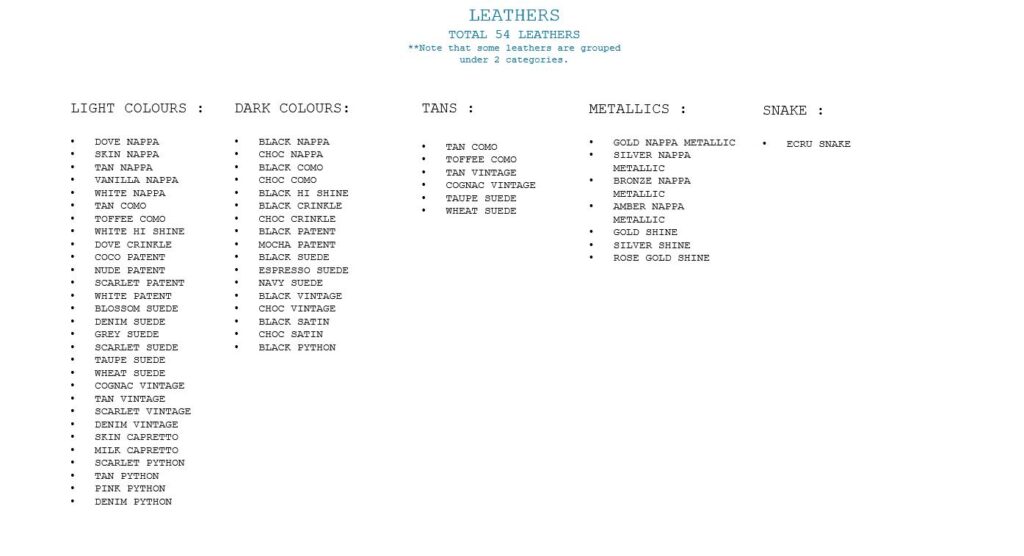

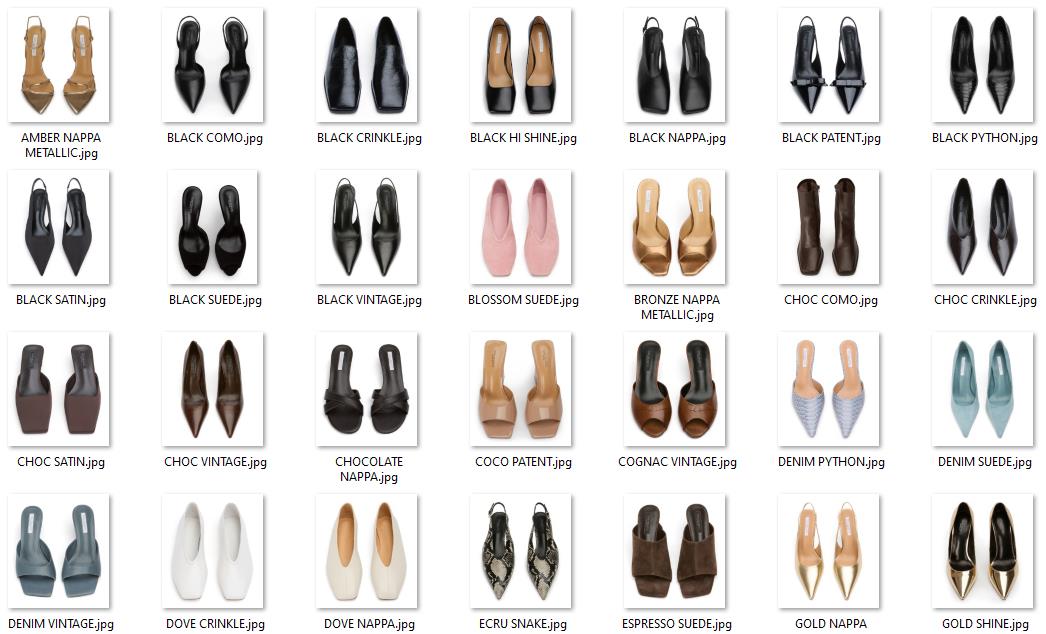

- Scope: 15 styles, 54 materials, 704 combinations, GLB files,

- Outputs: Photoreal stills, Shopify-ready GLB,

- Service: 3D Product Rendering Services.

- Why it worked: Proper communication, Clean approach, Access to awesome resources, Teamwork.

Discovery and Scoping.

Discovery and Scoping

After a few emails back and forth, we kicked off with shared goals and a clear plan. We decided to work with two shoe models first to standardize the production procedure. We confirmed we could generate full colorways from a single hero photo plus a color swatch, and the client provided the complete list of styles and finishes.

Modeling and Shape Lock

We started with clay renders to confirm proportions and silhouette. If it reads right in gray, it will look right in leather.

We received feedback from Maddison (Project co-ordinator) on behalf of their product team based on the clay renderings we delivered. We received revision requests for a couple of shoes (Hallie and Tiffany). On Hallie, the instep looked tight, so we opened the entry to read more wearable. On Tiffany, there was a slight kink in the front strap; we refined the curvature for clean hero angles and a smoother silhouette.

It matters because in clay previews, reflections, and lights won’t hide flaws in shape or missed detail.

Material Look-Dev and Library Build

We built the full material library from the client’s reference photos, recreating textures and finishes one-to-one. To validate accuracy, we applied each material to a single master shoe under standardized lighting and ran internal QA. After fine-tuning, we shared that master shoe, containing all materials, for client review. Following one revision pass, we hit the target look and locked the library for production.

Why it matters: We will not receive revision requests on materials for any future shoes.

As the 3D Models are approved, materials and lighting are approved, we started producing 3D product rendering for the rest of the shoe models and their variations. Reached 704 combinations with consistent lighting and material.

Interactive 3D Viewer: Explore one of the Tony Bianco shoe models below in 3D. Rotate, zoom, and inspect the materials and detailing in real time.

Wrapping Up

We wrapped by reinforcing how the pipeline consistently overdelivers on quality and scale, then positioned clear next steps for a broader rollout. Deliverables included master 3D models for 15 footwear styles, 54 leather types, and 704 product 3D models for seamless website upload. Compared to traditional photography, this approach accelerates time to market since new colorways require no reshoots, ensures consistency with a single calibrated lighting setup across all SKUs, controls costs by building once and reusing assets in future seasons, and remains future proof because new finishes plug into the same pipeline.

Thinking About Doing This For Your Brand

If you’re juggling colorways, waiting on late samples, or overspending on reshoots, CGI product rendering streamlines everything. Start with one hero style, lock the look, then scale across every finish with consistent quality.

Additional benefits: faster launches before samples exist, endless variants from one master model, omnichannel-ready assets (packshots, hero angles, 360s), retailer-compliant outputs (GLB/USDZ, exact specs), lower long-term costs, photoreal design validation, easy A/B testing, localization at scale, and fewer returns thanks to accurate visuals.

Explore our complete 3D Rendering Services

Or visit our 3d visualization portfolio. Want a quick estimate using your own references and swatches? Share one style and two finishes. We’ll reply with a simple plan, a clear price, and a realistic timeline.