About The Case Study

The client:

A footwear manufacturer exploring new ways to build a large-scale digital catalog for over 2,000 products each year, primarily for Amazon and other eCommerce platforms.

Software Used:

Autodesk 3ds Max, Blender, Substance 3D Painter, RizomUV, Adobe Photoshop, Babylon.js Viewer

Services Included:

The Situation

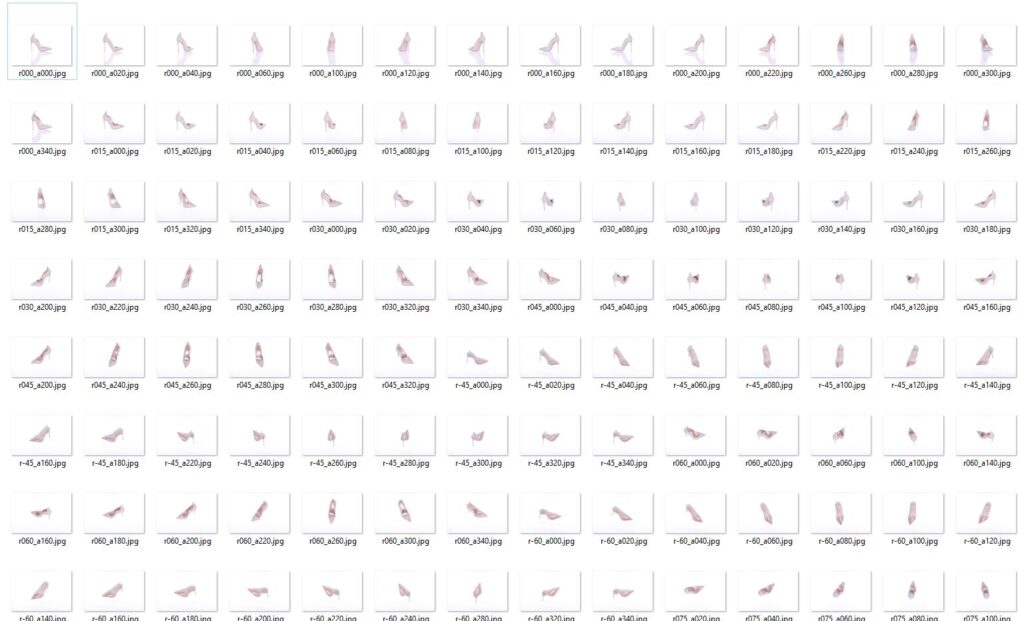

Solanum Shoes was testing a photogrammetry system (PhotoRobot) that promised fast, automated 3D generation using photos. The idea was simple: take a series of photos of each shoe, let the software turn them into a 3D file (USDZ), make a few tweaks if needed, and use them on platforms like Amazon.

But after trying it out, they realized something: the results looked off. Some 3D files came out messy—blurry details, incorrect shapes, and surface issues. They didn’t have a 3D artist in-house, so they reached out to us to help fix the files and explore other options.

What They Needed Help With

-

Fixing USDZ files generated by PhotoRobot.

-

Creating GLB files suitable for Amazon listings.

-

Comparing quality between automated scans vs. manual 3D modeling.

-

Understanding the costs of 3D Rendering and turnaround time at scale.

Our Approach

We offered to test both options—fixing the scanned files and creating new 3D models from scratch using their product photos. This way, they could directly compare the results and decide what made more sense for their workflow.

We also kept everything flexible: sent files in both GLB (for Windows) and USDZ (for Mac), shared turnaround times, and built a transparent pricing model they could scale up later.

Fixing the Scanned Files

We tried multiple tools (even Blender), but cleaning up the scans took around 4–7 hours per shoe—and the results still didn’t look great. For certain shapes and materials, the automated system just couldn’t capture the needed precision.

Modeling from Photos

The manually created models were sharper, cleaner, and more detailed. Each took about 10–12 hours after process optimizations (initially 18–19). We only needed 5–6 casual product photos per style.

Making Edits Later

Color changes (same shoe): ~$10 and done in a few minutes.

Material swaps (like changing leather to canvas): ~$30 and takes up to an hour.

No need to rephotograph if the shape stays the same.

Here’s a quick breakdown:

| Task | Time per Shoe | Notes |

| New 3D Model from Photos | 8–12 hours | Sharper quality, scalable for 2K+ units |

| Fixing USDZ (photogrammetry output) | 4–7 hours | Less quality, more manual effort |

| Color Change (same geometry) | ~5 mins | Simple recoloring |

| Material/Texture Change | 30–60 mins | Includes realistic surface mapping |

Client's Reaction

They liked the clarity of comparison and appreciated our transparency. While the scan-fix method seemed like a shortcut, the side-by-side results helped the team see why it’s not a viable long-term solution for their products.

Final Thoughts

Automated tools sound great on paper, but when you need consistent quality at scale, manual modeling still leads the way. For brands investing in visual presentation, especially on platforms like Amazon, clean and accurate 3D models make a difference. This project showed that taking the time to test both paths can lead to smarter decisions and better results.

If you would like to discuss your 3D Rendering project with us, please reach out to [email protected]. Take a look at our Portfolio to get inspired!